The world of architecture is undergoing a remarkable transformation thanks to the advent of cutting-edge 3D printing technologies. Where once architects relied on painstakingly crafted scale models or computer-generated visualizations alone, they now have the power to transform digital concepts into tangible, three-dimensional prototypes at unprecedented speeds. By integrating 3D printing into their design workflows, architects can enhance precision, reduce waste, experiment with a wider range of materials, and even consider entirely new approaches to building construction.

Within this shift, certain 3D printing tools, software solutions, and materials have emerged as major influencers in how architects conceptualize, present, and realize their ideas. From producing complex miniatures that help clients visualize every detail of a proposed structure, to generating full-scale building components that promise to disrupt traditional construction methods, 3D printing is revolutionizing architecture from the ground up.

This comprehensive article will delve into the leading 3D printing devices suitable for architectural work, discuss the materials that make innovation possible, outline the benefits and challenges of integrating these processes, and explore real-world applications that demonstrate how 3D printing is reshaping the future of design and construction. We will also expand on best practices, sustainable solutions, regulatory considerations, and the evolving tools and techniques that architects can leverage to stay competitive. By shedding light on these aspects, we aim to offer a deep, informative guide that architects, students, and enthusiasts can use to understand and embrace 3D printing in architecture.

Understanding the Core Principles of 3D Printing in Architecture

Before diving into specific tools and applications, it is crucial to understand how 3D printing works within the architectural landscape. At its core, 3D printing—also known as additive manufacturing—involves translating digital 3D models created with CAD (Computer-Aided Design) software into tangible objects. This process typically unfolds as follows:

A. Digital Modeling: Architects start with detailed designs using advanced CAD or Building Information Modeling (BIM) software. These digital blueprints are then transformed into 3D data files (often in formats like STL).

B. Slicing the Model: Specialized slicing software converts the 3D model into thin cross-sectional layers. The printer reads these layers and follows them sequentially during the printing process.

C. Layer-by-Layer Fabrication: The 3D printer builds the object layer by layer, depositing material in precise increments according to the sliced model’s instructions. This additive approach can create complex geometries unattainable through traditional subtractive methods like carving or milling.

D. Material Curing and Post-Processing: Depending on the printing technology and material, the printed object may require curing under UV light, heat treatments, or chemical baths to achieve final hardness, smoothness, or desired mechanical properties.

In architecture, this process allows for everything from conceptual models to structural prototypes. The key advantage is the capacity to visualize, test, and iterate on physical forms rapidly. By understanding these basics, architects can better integrate 3D printing into their creative workflows.

Top 3D Printing Tools Elevating Architectural Model Making

With numerous 3D printers available, certain models have earned particular acclaim within architecture for their reliability, detail, and material versatility. Below are some leading 3D printing tools currently influencing the industry:

1. Stratasys Fortus 450mc

Overview: The Stratasys Fortus 450mc stands out as a professional-grade 3D printer highly regarded for its robustness and versatility. It caters to architects who need to produce durable, functional models that can withstand rigorous testing or represent structural components. Its engineering-level thermoplastics and fine resolution help architects explore intricate details at an accelerated pace.

Key Features:

A. Broad Material Compatibility: From ABS to high-performance plastics that mimic engineering materials, architects can experiment with countless polymers suited to structural mock-ups.

B. Precision and Strength: The resulting prints boast consistent layer adhesion, dimensional accuracy, and mechanical strength, suitable for load-bearing prototypes or building components.

C. Streamlined Workflow: Integration with advanced software makes the entire pipeline—from CAD design to printed part—smooth and efficient.

2. Formlabs Form 3

Overview: Renowned for its resin-based SLA (Stereolithography) process, the Formlabs Form 3 excels at producing ultra-detailed architectural models. Its precision and smooth surface finishes make it ideal for client presentations, design competitions, and intricate elements like façade ornaments or interior details.

Key Features:

A. High Resolution: The laser-based SLA technology can create exceptionally fine details that highlight a building’s texture and intricate decorative motifs.

B. Versatile Resin Selection: Architects can choose from a variety of resins—standard, tough, rigid, or even bio-based—to produce models that meet both aesthetic and functional requirements.

C. Reliability: Its user-friendly interface and reliable performance make it a dependable tool for architectural firms of all sizes.

3. WASP 3D Printers (Concrete Printing)

Overview: WASP (World’s Advanced Saving Project) offers large-format 3D printers capable of extruding concrete, a massive leap forward in the ability to print full-scale structures. This approach is revolutionizing the construction process, making it possible to fabricate load-bearing walls, pavilions, and even entire small homes directly from digital designs.

Key Features:

A. Large-Scale Construction: WASP printers can handle bulky materials like clay or concrete, bringing the dream of 3D-printed buildings into reality.

B. Sustainable Solutions: By using locally sourced materials and focusing on eco-friendly construction, WASP aligns with growing demands for sustainable and affordable housing solutions.

C. Structural Innovation: Complex geometries, previously cost-prohibitive or difficult to achieve, can now be realized with less material waste.

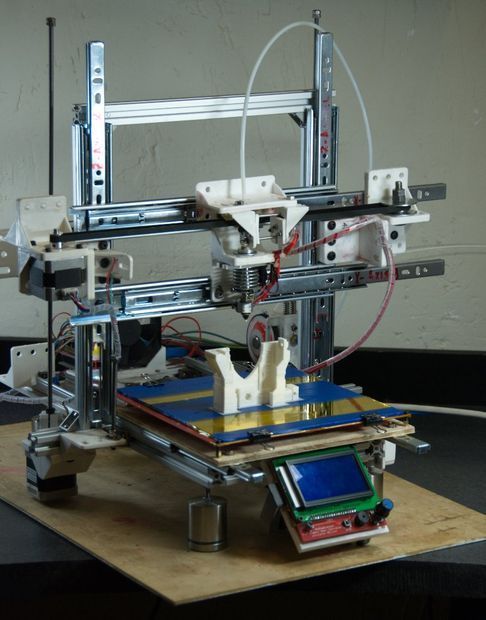

4. LulzBot TAZ 6

Overview: The LulzBot TAZ 6, though not as large-scale as WASP or as industrial-grade as Stratasys, offers a more accessible price point and material flexibility. It’s well-suited for architectural firms or students who want a reliable tool to quickly prototype designs without breaking the bank.

Key Features:

A. Open-Source Ecosystem: Its open-platform design allows compatibility with a broad range of materials, from PLA and ABS to specialty filaments.

B. Ease of Use: The user-friendly interface and automatic bed-leveling make printing simple for newcomers and experienced architects alike.

C. Good Value: For its price, it offers stable prints, decent resolution, and dependable performance, making it a practical choice for iterative concept models and early-stage prototypes.

Materials Empowering Architectural 3D Printing

The choice of material is critical in determining the functionality, aesthetics, and durability of the printed architectural model. Materials must be selected based on the purpose of the prototype—whether it’s a delicate scale model, a functional component, or a full-scale structural element.

Plastics (ABS, PLA, and More)

Plastics remain the most common choice for 3D-printed architectural models. They are lightweight, relatively inexpensive, and easy to print.

A. ABS (Acrylonitrile Butadiene Styrene): Strong and slightly flexible, ABS is suitable for functional prototypes that may be handled frequently.

B. PLA (Polylactic Acid): Derived from renewable resources like cornstarch, PLA is biodegradable and emits fewer fumes. It’s popular for simple, environmentally conscious prototypes.

C. PETG (Polyethylene Terephthalate Glycol): Offering a balance of strength, flexibility, and clarity, PETG is useful for models needing durability and a polished finish.

Concrete and Mortar Mixtures

Concrete 3D printing is paving the way for revolutionary building techniques.

A. Reinforced Mortars: Incorporating fibers or additives enhances tensile strength and reduces cracking.

B. Low-CO2 Concretes: Some mixes incorporate industrial waste or alternative binders to reduce the overall environmental footprint.

C. On-Demand Formwork: Concrete printers can create complex, custom formwork faster, reducing labor and waste on-site.

Metals (Stainless Steel, Titanium, and More)

Metal 3D printing remains cutting-edge and less common in mainstream architectural practice but offers compelling advantages:

A. Stainless Steel: Ideal for custom façade elements, structural brackets, or decorative detailing that requires strength and longevity.

B. Titanium: Extremely strong yet lightweight, titanium components can reduce structural weight while maintaining rigidity, though currently more expensive and specialized.

C. Aluminum Alloys: Used for lightweight but strong parts that can integrate seamlessly into building systems.

Resins for High Detail

Resins excel at capturing fine details. They are ideal for showcase models that must communicate complex geometry or surface treatments:

A. Standard Resins: Offer smooth finishes suitable for general purpose architectural miniatures.

B. Engineering Resins: Designed for durability and functional testing, engineering resins can mimic final materials closely.

C. Transparent Resins: Allow architects to print translucent elements, helping to visualize interior lighting conditions or façade transparency.

Benefits of Embracing 3D Printing in Architectural Practice

The integration of 3D printing into architectural workflows confers several tangible benefits:

A. Speed and Efficiency: Traditional model-making can be time-consuming and labor-intensive. With 3D printing, architects can transform designs into physical objects quickly—sometimes in hours—streamlining the iterative design process.

B. Enhanced Precision: Modern 3D printers can achieve impressive tolerances, ensuring that scale models or prototypes are faithful representations of the original CAD data, helping architects identify design flaws early.

C. Cost-Effectiveness: While initial investments in printers and materials can be significant, over time, 3D printing reduces labor costs and material waste. Revisions are handled by updating digital files rather than recreating models from scratch.

D. Design Freedom: Complex geometries that were once difficult or impossible to fabricate can now be produced with relative ease. Architects can explore organic shapes, intricate lattice structures, and biomimetic forms with fewer constraints.

E. Client Engagement: Physical models add tangible value during client presentations. Clients can hold and examine models, providing a more immersive understanding of the design than flat renderings.

F. Sustainability: By using recyclable materials, optimizing shapes for reduced material use, and printing on-demand components, 3D printing can contribute to more sustainable building practices.

Real-World Applications of 3D Printing in Architecture

The influence of 3D printing extends well beyond conceptual modeling. Several real-world applications demonstrate how architects are using these tools to enhance projects and push the boundaries of construction.

Prototyping and Scale Models

Traditionally, architects relied on foam, cardboard, or balsa wood to create scale models. These manual methods were time-consuming, prone to human error, and less flexible for modifications. With 3D printing:

A. Complex Geometries: Intricate facades, curved walls, and interlocking components are easier to replicate accurately.

B. Rapid Iteration: When clients request changes, updating the digital file and reprinting is much faster than rebuilding a scale model by hand.

C. Showcasing Context: Architects can print site models that encompass topography, neighboring buildings, and infrastructure, offering a holistic view of how the structure fits into its environment.

Full-Scale Construction Projects

The concept of 3D printing entire buildings might sound futuristic, but it’s already happening.

A. Residential Construction: Several companies have successfully printed entire homes using large-scale 3D printers that extrude concrete. These homes can be built faster and with fewer laborers.

B. Emergency Shelters: In disaster-stricken areas, 3D-printed shelters can be erected quickly, providing safe, temporary housing solutions at lower costs.

C. Modular Components: Printing modules off-site and assembling them at the construction site reduces transportation costs and streamlines the process.

Historic Preservation and Restoration

3D printing also plays a vital role in preserving cultural heritage.

A. Replicating Ornaments: Missing or damaged architectural details in historic buildings can be recreated from archival photographs or 3D scans, ensuring authenticity in restoration efforts.

B. Non-Invasive Techniques: Instead of carving new stone or wood, 3D printing offers a less intrusive method of restoring delicate facades.

C. Archival Documentation: Architectural elements can be digitally archived and reprinted in the future, preserving cultural identity for generations.

Overcoming Challenges and Limitations

Despite its numerous advantages, 3D printing for architecture is not without challenges. Recognizing and addressing these issues is crucial for architects who want to maximize the technology’s potential.

A. Material Limitations: While innovation is ongoing, not all building materials are readily available for 3D printing. Certain composites or advanced polymers may still be in development stages or cost-prohibitive.

B. Print Size Constraints: Standard desktop 3D printers have limited build volumes, making large-scale models tricky. Although large-format printers exist, they are often more expensive and require dedicated space.

C. Regulations and Building Codes: The construction industry is heavily regulated. Adopting 3D-printed components in load-bearing structures must comply with local codes, ensuring safety and structural integrity. Architects, engineers, and contractors must collaborate to establish standards and ensure compliance.

D. Maintenance and Equipment Costs: High-quality 3D printers and specialty materials can be costly. Maintenance, calibration, and the learning curve associated with these tools might pose barriers for smaller firms or independent architects.

E. Skilled Labor Shortage: Operating and maintaining 3D printing equipment requires training. Architectural firms may need to invest in professional development or hire dedicated specialists, increasing overhead costs.

The Future of 3D Printing in Architecture

As the technology matures, 3D printing promises to bring about even more transformative changes to architecture. Emerging trends and developments point toward a future where entire cities could be planned, optimized, and constructed using additive manufacturing techniques.

Integration with BIM and AI

Building Information Modeling (BIM) software is already revolutionizing how architects plan and document projects. In the future:

A. Automated Design Adjustments: AI-driven software can analyze building performance, detect structural weaknesses, or optimize material usage, then directly update the digital model for 3D printing.

B. Smart Material Allocation: Intelligent tools will recommend the best materials for specific components, ensuring the printed output meets structural and environmental performance criteria.

C. Digital Twins: Physical models printed from BIM data can be continuously updated as the design evolves, helping architects maintain consistent alignment between the digital and physical realms.

Rapid Urban Prototyping

As population pressures and urban challenges grow, 3D printing could offer innovative solutions:

A. On-Site Fabrication: Mobile 3D printers transported by truck or drone could print building components directly on location, reducing logistics and lead times.

B. Temporary Structures: Sporting events, festivals, and emergency situations may benefit from quickly printed temporary pavilions or shelters, which can be disassembled and recycled afterward.

C. Circular Economy: The ability to grind down and reuse printed materials would foster a circular construction economy, minimizing environmental impact.

Regulatory Evolution and Standardization

For 3D-printed architecture to become mainstream, regulatory bodies will need to evolve:

A. Building Codes for Additive Manufacturing: New standards will likely emerge to ensure the structural integrity, fire resistance, and durability of 3D-printed elements.

B. Professional Certifications: As the technology proliferates, architects and engineers may obtain specialized certifications ensuring they understand the safe and effective use of 3D printing.

C. Environmental Regulations: Governments may incentivize additive manufacturing for its ability to reduce construction waste and carbon footprints, driving more architects to adopt the technology.

Best Practices for Implementing 3D Printing in an Architectural Firm

Architects looking to integrate 3D printing into their daily workflows can follow certain best practices to ensure they get the most out of the technology:

A. Invest in Training: Ensure that team members understand the full capabilities and limitations of 3D printers. Skilled operators and designers can optimize print settings and troubleshoot issues efficiently.

B. Start Small and Scale Up: Begin by using 3D printing for concept models, then gradually explore more complex applications. As confidence and expertise grow, firms can tackle larger, more ambitious projects.

C. Collaborate with Material Experts: Partner with material scientists or suppliers who can recommend optimal materials for specific architectural applications, ensuring structural integrity and cost-effectiveness.

D. Iterative Prototyping: Take advantage of the rapid iteration cycle. Print multiple versions of a model to test various design alternatives, structural solutions, or façade treatments.

E. Leverage Software Tools: Use slicing software and advanced CAD tools specifically designed for additive manufacturing. These tools help optimize model orientation, support structures, and material usage.

F. Maintenance and Calibration: Regularly maintain equipment and calibrate printers for accuracy. Keep a log of best print settings, material sources, and techniques that yield the best results.

Sustainability and Eco-Friendly Innovations

As environmental concerns grow, sustainable approaches to construction are increasingly vital. 3D printing has the potential to make architecture greener:

A. Reduced Material Waste: Traditional methods often involve cutting blocks of material, discarding scraps. With additive manufacturing, material is only added where needed, minimizing waste.

B. Local Materials: Some 3D printing technologies can use materials sourced locally (e.g., clay or soil-based mixes), reducing transportation emissions and fostering regional self-sufficiency.

C. Energy Efficiency: As 3D printers become more energy-efficient and integrate renewable energy sources, the overall carbon footprint of the construction process can decrease.

D. Biodegradable Filaments: Research into biodegradable filaments and resins paves the way for architectural models that have a reduced environmental impact. For conceptual models that don’t need longevity, these eco-friendly materials are a strong option.

Inspiring Case Studies

To fully appreciate the practical impact of 3D printing in architecture, consider a few notable projects:

A. MX3D Bridge (Amsterdam): A 3D-printed steel pedestrian bridge now spans a canal in Amsterdam. Created by robotic arms depositing metal layer by layer, this project demonstrates how additive manufacturing can produce fully functional infrastructure that blends art and engineering.

B. Winsun 3D-Printed Houses (China): Chinese company Winsun used giant 3D printers to fabricate components for entire homes, constructed at unprecedented speeds and reduced labor costs. These projects highlight the potential of large-scale 3D printing to address housing shortages.

C. 3D-Printed Mud House (Italy): WASP teamed with materials experts to print eco-friendly housing from local clay. This innovative structure represents a fusion of tradition (earthen construction) with modern technology, producing affordable and sustainable dwellings.

D. Foster + Partners Prototypes: Leading architectural firm Foster + Partners has experimented with 3D printing for complex facade studies and component prototyping, showcasing how even top-tier architects leverage this technology to refine their iconic designs.

The Role of Software in Advancing 3D Printed Architecture

While hardware steals much of the spotlight, software advances are equally critical:

A. Parametric Design: Tools like Grasshopper for Rhino allow architects to create parametric models that can be easily adjusted. With a few parameter tweaks, a new model variant can be printed, supporting rapid experimentation.

B. Generative Design: AI-assisted generative design software can suggest forms optimized for structural efficiency, daylight access, or material use. Architects can print these suggestions to assess feasibility in the real world.

C. AR and VR Integration: By combining 3D printing with augmented and virtual reality, architects can shift seamlessly between digital and physical realms, using mixed-media presentations to impress clients and refine concepts.

Embracing the Paradigm Shift

Architects who hesitate to adopt 3D printing might find themselves at a disadvantage in an increasingly competitive market. Embracing 3D printing isn’t just about acquiring the latest gadget—it’s about shifting the mindset toward a more iterative, experimental, and sustainable approach to architecture.

A. Cultural Change in Firms: Architectural practices must foster a culture of innovation, encouraging staff to learn, experiment, and share knowledge about additive manufacturing technologies.

B. Client Education: Many clients may be unfamiliar with 3D printing and its benefits. Educating them about how physical prototypes improve communication, reduce misunderstandings, and refine design outcomes can lead to greater buy-in and enthusiasm.

C. Interdisciplinary Collaboration: The sweet spot for 3D printing often emerges at the intersection of architecture, engineering, manufacturing, and materials science. Collaboration across these fields ensures well-rounded solutions that address multiple dimensions of a project’s needs.

Conclusion

3D printing is redefining the architectural landscape, offering unprecedented opportunities for creativity, efficiency, precision, and sustainability. From small scale models that capture every ornate detail of a building’s façade to full-scale printed structures that challenge conventional construction techniques, these technologies allow architects to push the boundaries of design. The top 3D printing tools available today—ranging from high-end industrial systems like the Stratasys Fortus 450mc to cutting-edge concrete printers such as WASP—provide a robust toolkit for professionals eager to harness the future of building.

As the technology continues to evolve, architects can look forward to seamless integration with AI-driven design, faster construction times, more sustainable materials, and a host of regulatory frameworks that will shape a new era in building. Embracing 3D printing is no longer a question of if, but when and how. Those who adopt these tools, invest in the necessary training, and champion innovation within their firms will find themselves at the forefront of architectural practice—delivering designs that are not only visionary and practical, but also kinder to the environment and more responsive to the needs of an ever-changing world.